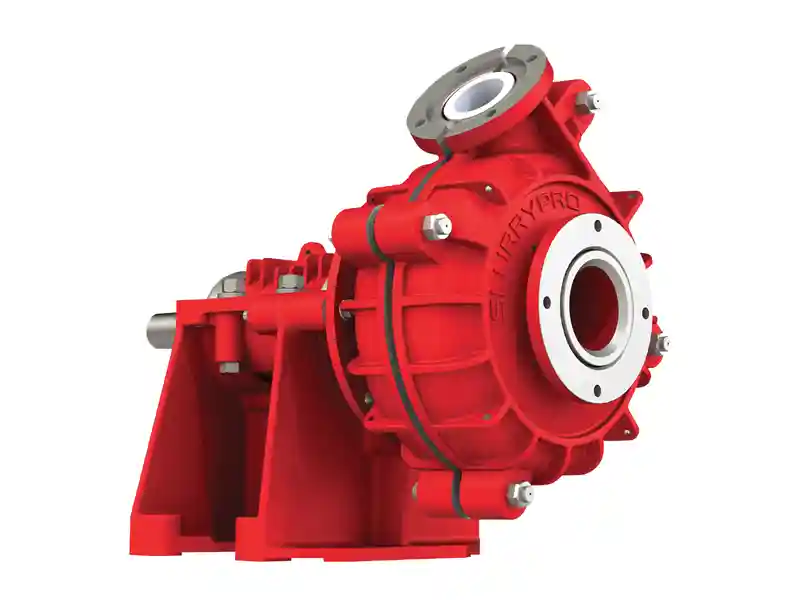

High-performance guarantee right across the SlurryPro range

Our slurry pumps are designed to perform in the most demanding industrial conditions. Lined with a unique elastomeric compound that’s comparable to rubber, but with superior wear-resistance properties, these high-density slurry pumps are built for durability. SlurryPro slurry pumps also feature a range of interchangeable parts compatible with most common slurry pump brands, from impellers to bearings, allowing for cost-effective repairs.

They offer flexibility, whether you’re specifying new pumps or upgrading existing ones. And better yet, our slurry pumps enable you to continue using your current pump and pipework configuration, reducing the need for costly system overhauls.

Most importantly, you’ll always have access to technical assistance if you purchase slurry pumps and parts from our range, regardless of where you’re located. The SlurryPro team has a service division set up right here in Australia, which means quicker repair turnarounds, part replacements, and on-site diagnostics when needed.

SlurryPro slurry pumps provide superior wear life, reduced lifetime costs, and easy maintenance. Our extensive range includes 240V to 1000V slurry pumps, addressing a broad spectrum of industrial needs. Specifically designed for pumping highly abrasive, high-density slurry, SlurryPro pumps are ideal for the mining industry, but versatile enough for any slurry pumping application.

Key features of our slurry pumps:

- rubber and metal lined pumps

- flows up to 5,000 L/s

- heads up to 100 m

- removal cartridge-type bearing assembly

- split casing for easy maintenance

- oversize shaft and bearings for zero shaft deflection

- moulded impeller for stronger wear resistance

- range of different high-tech sealing systems

- liners available in different materials for greater chemical resistance

- interchangeable wearing parts with most slurry pump brands

- low maintenance costs

Critical dimensions are interchangeable with other common centrifugal slurry pump designs, making it easy to upgrade to SlurryPro.

No matter what you require for your specific project, talk to our pump experts for comprehensive advice today.

We also offer a range of other pumps, including trash, centrifugal pumps, and drum pumps. Browse all the pumps here.