Air operated diaphragm pumps are tremendously flexible and easy to install. However, like any pump, they do have their technical limits when handling air or liquid pressure, which are defined precisely by the manufacturer for your model. But what sort of air pressure range do diaphragm pumps typically use?

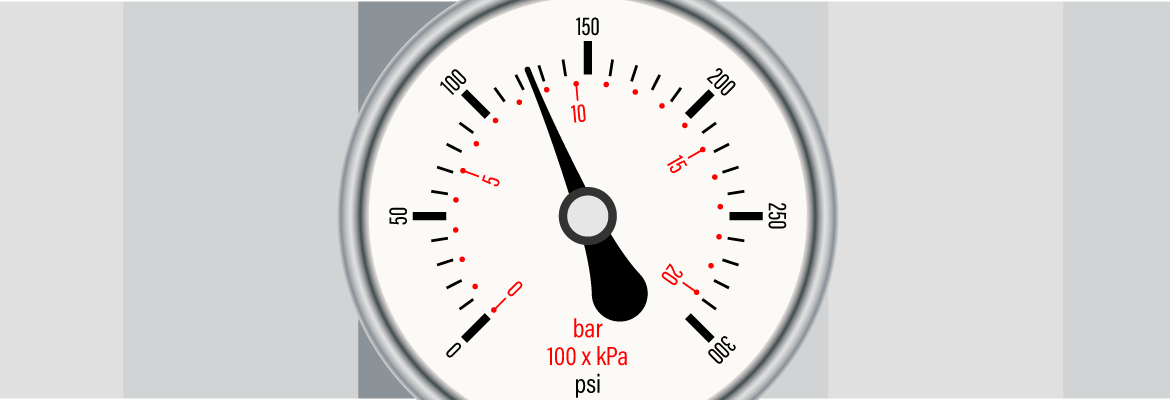

Most air operated diaphragm pumps can handle air pressures up to 125 psi or 8.6 bar. Operating a diaphragm pump outside of these ranges can result in failure.

In order to monitor the air pressure of your pump, it is recommended to install an air regulator on the air inlet, not only to control the pressure, but also the flowrate. An alternative to the air regulator is to use a valve on the air inlet which controls the flowrate, but does not necessarily maintain the air pressure.

What happens if you exceed a diaphragm pump’s pressure range?

If the inlet pressure entering your diaphragm pump is beyond its recommended range, then this can cause several problems, which can include:

- the air operated diaphragm pump’s valve ball, closest to the suction, will be pushed around vigorously causing it to be removed from its seat

- if the diaphragm pump is started at the limit of its pressure range, some issues may arise as the pump will not be filled with liquid yet, therefore, the valve seat will not close properly, stopping the necessary vacuum from forming

- consistent use at high pressure can cause lasting damage to the pump, including the diaphragm and other key internal components

Recommended air operated diaphragm pumps

Global Pumps stock a large range of diaphragm pumps, which come in various materials that are suitable for pumping different types of chemicals and liquids.

Key features of these pumps are that they are portable and come in both metallic and non-metallic types. They are able to run dry, self-prime and are easy to setup and maintain.

Contact our team today for a free quote, as well as advice or pump recommendations so you can choose the best air operated diaphragm pump for your site.