Find out how to determine the efficiency of your pump with the team at Global Pumps.

Determine the efficiency of your pump before you waste money, water and electricity!

Determine the efficiency of your pump before you waste money, water and electricity!

It is important that before selecting and purchasing a pump you are aware of its efficiency for the application. Selecting an appropriate pump will conserve fuel, electricity and decrease downtime and maintenance costs. If you select a pump that is inefficient, or not suitable for the application, it will be costly for both plant and equipment, and could waste or damage the goods being pumped.

What is pump efficiency?

A pump’s efficiency is determined by how effectively the pump can convert one form of energy to another, based on the difference between the horsepower going into and out of a pump. Ideally, the horsepower entering the pump would equal the horsepower exiting the pump; making the pumping system 100% efficient.

It is important that you calculate the pump efficiency to determine if you have a powerful enough pump for the application. This is generally done prior to the purchase of a pump, but should be considered when repurposing an already owned pump.

The horsepower is delivered to the pump from a power unit, commonly an electric motor or engine.

The flow rate and total head need to be calculated to properly determine the pump’s efficiency.

Pump Flow Rate

The flow rate is the total volume of liquid / fluid that passes through a fixed point over time. It is commonly measured using a flow meter – which can calculate the flow rate at whatever units required.

Total Head

The total head is determined by measuring the distance from the source of the liquid / fluid to the output of the pump, as well as the pressure the pump is producing at the pump outlet.

Determining your pump efficiency

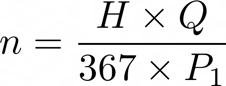

In order to calculate the pump efficiency, you could use the following formula:

Q = flow in cubic meters per hour (m3/h)

H = pump head, or pressure, in meters (m)

P1 = motor power consumption in kilowatts (kW)

This formula is appropriate for both motor and pump-end efficiency as one total number.

Monitoring your pump’s efficiency

Once the pump has been installed, it is advised that all performance parameters are recorded – flow, pressure and power consumption. This will benchmark data and allow you to monitor the efficiency of the pump over its life.

Deviations to the parameters can be caused by:

- Operating conditions of the pump have changed: if a pump must deliver at a higher head, the duty point moves to the left on the pump curve and subsequently delivers less flow.

- Flow or pressure requirements have changed: consider changing the pump if the flow requirements change significantly.

- Pump is losing efficiency: this can be caused by, cavitation, increase in friction loss, wear from inclusions in the fluid, or bad power supply.

For more information on how to determine your pump’s efficiency, or to chat to an expert about selecting the right pump for your application, contact Global Pumps. Our team of experts have worked across multiple industries and are on hand to assist you with queries or concerns.

As many Australian businesses look to be more efficient in their production or manufacturing, it’s important you consider the versatility of your pumping system. Before producing alternative products or pumping a new chemical or fluid, chat to a team member to ensure you are not damaging your pump.

Global Pumps offer forty-years’ experience across multiple industries and can assist you re-purpose your system to meet alternative product demands!