The impeller is one of the most critical parts of a centrifugal pump. The rotating iron or steel disc features vanes and is responsible for transferring energy from the motor, to the fluid being pumped. This is done by accelerating the fluid radially outwards from the centre of the impeller.

In some instances, impeller trimming is required to adjust the pump's performance to a required duty point. In this blog, our team share their knowledge on the topic and describe what sort of changes you may notice when the impeller is trimmed. The diameter of the impeller is trimmed in these instances.

During the selection process, you pump expert might suggest trimming the impeller of a pump to meet the performance you require. When you trim an impeller, you'll notice a reduction in the head pressure, flow rate and power draw on the motor. In most instances, the performance curve of a centrifugal pump will detail the performance of a few impeller diameters - minimum to maximum allowable diameter. There are several things that may offer when the impeller vane is reduced:

Shift in performance.

The greater the impeller reduction and the higher the specific speed, the more the pump efficiency will decrease with impeller trimming. The change in your pump’s performance when the impeller diameter is reduced, can be predicted using affinity laws:

- Pump flow rate (Q) varies directly with the diameter (D), i.e. Q1 / Q2 = D1 / D2

- Pump head (H) varies with the square of the diameter (D), i.e. H1 / H2 = (D1 / D2)2

- Power absorbed varies with the cube of the diameter (D), i.e. P2 / P2 = (D1 / D2)3

The relationships between these elements adjust the head and flow rate represented on performance curves. Particularly if the impeller reduction is greater than 10% of the maximum size.

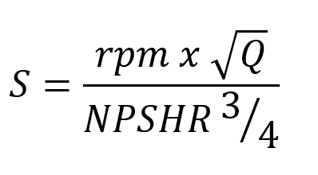

Net Positive Suction Head Required (NHSHR)

If the impeller reduction is greater than 5-10% of the maximum, it will subsequently increase the NPSHR, dependent on the impeller specific speed.

In this equation, the NPSHR should not change with changes in the impeller, if the flow and RPM remain constant - as there is no factor in the S equation that relates to impeller diameter.

Research suggests that trimming the impellers within the allowable impeller cut range on pumps with a low specific speed (Ns < 30 SI), reveal little, to no, impact on NPSHR.

If you are considering trimming the impeller beyond this range, recirculation between impeller discharge and the impeller inlet may disrupt the inlet flow, which increases the NPSHR.

Global Pumps suggest discussing your site’s requirements before selecting a pump and considering the impeller size. Whether you speak to an expert, or conduct research yourself, it’s important you consider all consequences of trimming the impeller or discuss it with the pump manufacturer.

Want advice from Global Pumps? Get in touch with our team today! We can conduct site visits across Australia and can customize the pumping system to suit your needs.