There comes a time in every good pump systems’ life where what once was adequate is now not good enough. The flow needs to increase, the lines get extended, or the operators just need that bit of extra momentum on the discharge. As pump experts, this isn’t the end of the world, we have several levers we can pull to help get that extra bit of pressure out of the pump and increase discharge pressure of centrifugal pumps to meet the new systems requirements.

A pump's main job is to provide flow, the pressure that we see in the line is not caused just because the pump is running, rather the pressure is caused because the pump is providing flow. The more flow the pump provides, the greater volume of fluid within the system, and this then builds pressure. Factors such as pipe length, pipe size, valves and discharge height all influence how much pressure is in the system.

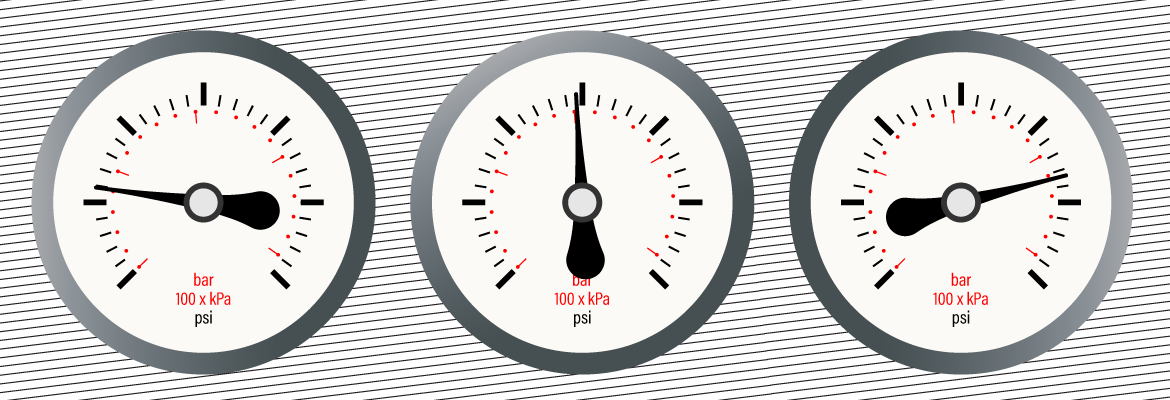

So to increase our discharge pressure, lets first of all look at our pump, has the impeller been trimmed to meet previous requirements? Has pump cavitation occurred? If so, we can increase the impeller to get that extra pressure. Inversely if the pump is providing too much pressure and we want to move its performance back down the curve we can trim the impeller. Centrifugal pumps have a maximum allowable discharge pressure based on pump performance, power, and strength, therefore monitoring your pump's uses and conducting regular maintenance is necessary to avoid downtime and any potential problems.

What speed is the pump running at? We can always look at speeding up the pump. This can be done with either a Variable Speed Drive, new belt, and pulleys, or in drastic circumstances a whole new motor. This has its limitations, but small changes can have significant effects on the performance of the pump.

If we just want extra flow, are there any obstructions we can remove? Unnecessary bends and valves greatly reduce the performance of the pump, so let’s look at eliminating them by ensuring the hose is the correct length. It is important to check whether the impeller is corroded and whether the pump is correctly primed.

A change in system requirements most certainly isn’t the end of the world and doesn’t always mean having to source a new pump. As experts in our field, the team at Global Pumps are well placed to help solve your pumping issues and keep you running with your current equipment as long as possible. We are committed to solving the tough challenges and finding the solution to your problems. Get in touch today for help with all your pumping requirements.