When purchasing a new pumping system, or upgrading an existing one, often the main considerations is the upfront cost of the pump itself. Although the capital cost only equals about 10% of the lifetime costs, there are other factors, such as spare parts, downtime, operational costs, and maintenance which are all important variables to consider.

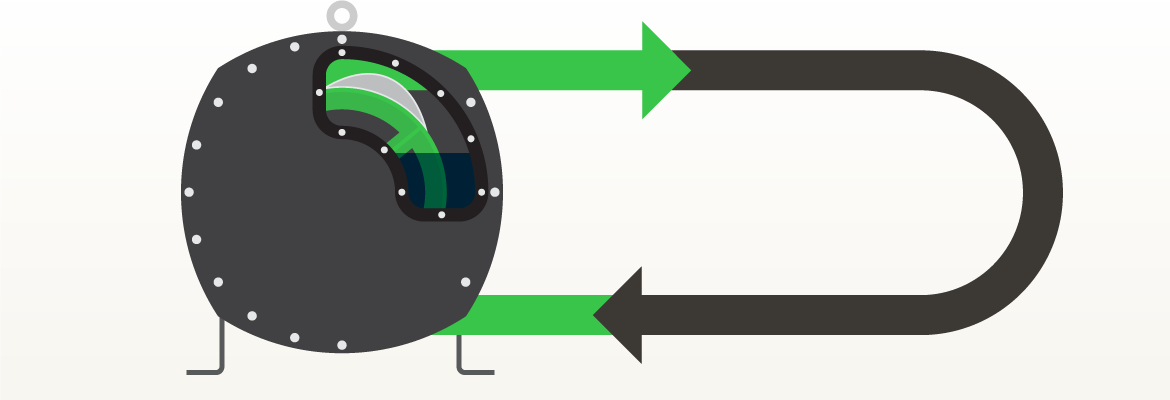

Hose pump failures and the associated downtime can be very costly events, but there are simple ways to reduce costs and maximise the pumps overall lifecycle. The solution is not always preventive maintenance, rather we should be looking at predictive maintenance. Preventive maintenance is scheduled based on asset conditions (only when necessary) while predictive maintenance is scheduled regularly, anticipating failure.

The Total Cost of Life is the total cost associated with your industrial pump from the point of procurement to the point of decommissioning and disposal. Analysing the Total Cost of Life of the pump will help Operations Manager or Plant Managers identify maintenance schedules and hidden costs, as well as be equipped with the necessary accessories and spare parts.

It is important to consider the following factors when analysing the lifecycle costs:

*Note: figures are from Top 10 Global Chemical Manufacturers, FY 2006

- spare parts: makes up 10% of overall cost over wear of life

- downtime: makes up 9% of overall cost over wear of life

- maintenance time: makes up 10% of overall cost over wear of life

- product loss: makes up 9% of overall cost over wear of life

- waste generation: makes up 7% of overall cost over wear of life

- safety measures: makes up 4% of overall cost over wear of life

Operators have little control over environmental, disposal and installation costs, but great control over maintenance, energy, and downtime costs. This means that you can apply predictive maintenance to your hose pumps to maximise their lifecycle. Another crucial factor is getting higher quality wearing parts such as a hose. Verderflex peristaltic hoses offer advanced hose construction with an even distribution of reinforcing, a textured finish, permanent colour coding for easy identification, and are designed to suit many applications. These hose characteristics add value and longevity to your pump, while decreasing the Total Cost of Life of your pump.

Through the implementation of an effective and consistent maintenance strategy, you will increase the life of your hose pump and reduce the Total Cost of Life associated with your pump.

If you are considering replacing or repairing your pumping system, and require more information, speak to a Global Pumps team member. With over forty years’ experience, Global Pumps can ensure you are operating efficiently and effectively. Contact Global Pumps for more information today!