Introducing the latest innovative solution developed by the Intrax group. Global Pumps, a member of the Intrax Group, are thrilled to present the SlurryPro Automatic Lubricator.

These automatic lubricators are a cost-effective alternative to manual lubrication for pumps and rotating equipment that require regular lubrication.

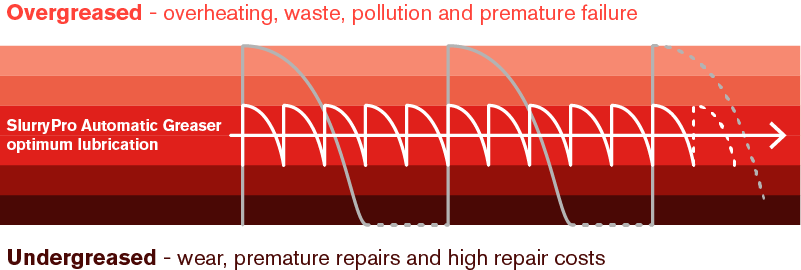

Global Pumps understand that greasing the bearings may be time consuming and can be missed. If you are under or over lubricating, the effects could be disastrous, with premature bearing or machine failure a common occurrence.

To learn more about this new Automatic Greaser and how it can change the operation of pumps, we had a chat to our team…

Q: What benefits do these SlurryPro Automatic Greasers provide users?

Project Team: It ensures the ideal amount of greasing is dispersed to maintain optimum operating conditions for the pump’s bearings.

Q: Without an Automatic Greaser, how do operators grease the pumps? How long does the process usually take?

Project Team: In a recent project, the greasing requirements for a range of slurry pumps were every 600 hours and 25 days of continuous operations, along with five shots from a grease gun into both bearings. However, this is not the case for all applications. Greasing requirements change based on the pump speed, bearing size and operating conditions. This means that across a site, the greasing requirements can be different from pump to pump.

It is an ongoing maintenance task, and if it is missed or forgotten can cause premature bearing failure.

Above: The SlurryPro Automatic Greaser offers continuous greasing, whilst manual greasing is inconsistent.

Q: Can you change the frequency the grease dispenses?

Project Team: There are seven settings to choose from. On the top of the device a number reflects the number of months the unit will last in an ambient temperature of 20 oC. The warmer it is, the faster the grease dispels. Once you set and activate the lubricator, it’s important to remember you can’t change the setting.

Q: What pumps do these Auto-Greasers suit?

Project Team: These greasers can be used on anything that requires grease lubrication.

Besides the automatic greasing capabilities, these devices also offer the following features:

- Easy to use, with no screws or tools required

- Hermetically sealed

- Wide operating temperature range

- No need for costly, time consuming manual lubrication

- Savings in labor costs and maintenance

- Reduction is lubricant consumption

- Lessen environmental impact

They also offer impressive savings across operational aspects of the business, including:

- Reduced costly downtime and failures

- Improved production performance

- Extend asset life

- Reduce maintenance costs

The SlurryPro Automatic Greasers simply the process of lubrication and ensure the exact lubricant is dispersed on the correct pump.

For more information on this latest innovation, or to find out if you can add an Automatic Greaser to your current pumping system, get in touch!