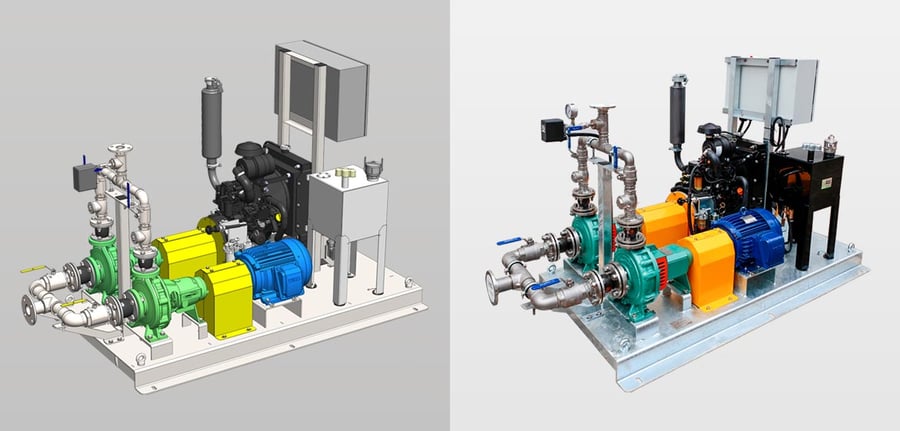

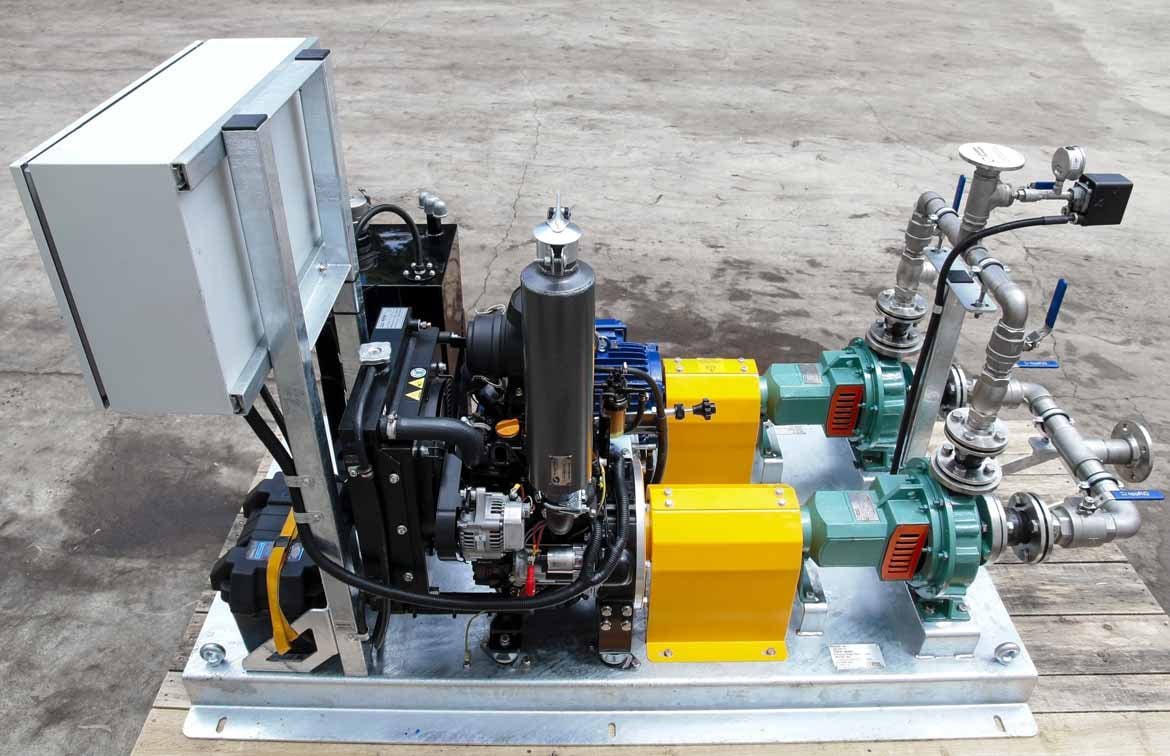

Global Pump’s project team was recently contacted by a mine site in Western Australia to produce a dual water pump skid for a safety shower and drinking water. The pump skid is designed to pump fresh water in remote areas where there may not always be access to electricity.

The challenges

Our team needed to source a diesel engine to fit to the pump that met the mine sites strict noise and pollution regulations. In addition to these regulations, a diesel controller was necessary to read the engines fuel level, oil pressure, engine speed and temperature. Pressure start/stop systems were also required in order to provide a continuous water flow; this works like opening and closing a tap.

Our solution

For this project, a water-cooled Isuzu Diesel Engine with a 27 L fuel tank was selected along with a diesel controller which was programmed to be BMS compatible. Regarding noise regulations, an acoustic cover was placed to muffle sounds in accordance with the mine sites requirements. The pressure start/stop system offered a flowrate of 10-20 m3/hr, which can vary depending on the motor size.

Project specifics

- SS316 suction and discharge manifolds/valves

- base available in galvanised mild steel, stainless steel or painted to customer requirements

- electrical controls are mounted within IP66 control box

- additional pressure tank available if required

- isolation valves ensure for easy maintenance

- rubber bellows used on both suction and discharge manifolds

- suction: 50 mm

- discharge: 32 mm

Global Pumps’ dedicated projects team incorporate engineering experts with a combined 47 years’ experience. Work with our team of engineers to find the reliable, Australian made solution for your site. Give our projects team a call today or get in touch with our sales team to learn more about dual pump skids.