Ethanol plant resolves pulsation issues and power limitations by switching to a Techniflo TB mag drive pump. Designed for handling corrosive slurries, the pump ensures efficient, leak-free transfer while maintaining required pressure and power constraints.

Challenge

An Ethanol plant in Australia required a pump to facilitate the transfer of a corrosive slurry into a filter press. The initial pump being utilised was a peristaltic hose pump which had pulsation issues and could only produce a 6-Bar maximum. The product being pumped was a 15% Sulphuric acid slurry with 30% solids concentration of up to 2mm in size - approximately half of the concentration being made up of solids that are less than 0.1mm.

The slurry is thixotropic, meaning that when it is not being agitated it can become thicker (up to approx. 200cPs). If it is kept agitated (at a temperature of above 50°C) it will remain reasonably fluid. The duty flow rate required was 120l/min @ 6-11Bar discharge pressure; the pressure would vary depending on the filter. Obviously the more clogged the filter became the higher the pressure was required. There was another requirement to the application in that the power consumption must be limited to 5.5kW.

Solution

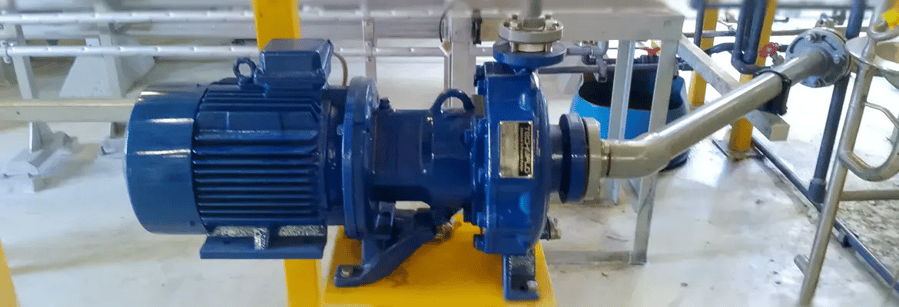

To be able to effectively transfer the corrosive slurry into the filter press, Global Pumps supplied a Techniflo TB mag drive pump model TB2x1x10C coupled to a 5.5kW motor. A variable speed drive had to be installed to prevent the pump from drawing more than 5.5kW of power. The Techniflo Magnetic Drive TB Series pump is specially designed to handle slurries with solid concentrations of up to 30% and particle sizes up to 6mm in size are possible. TB Series Techniflo Mag Drive Centrifugal Pumps clearance rings restrict solids greater than 0.1mm from entering the containment shell area, keeping all bearings and critical flow paths clear.

Result

Installing Global Pumps’ Techniflo magnetic driven pump was ideal as these pumps offer outstanding corrosion resistance and are an excellent leak free solution. This high level of efficiency was, and still is, beneficial not only to the company, but also to its environmental surroundings.