One of the most misunderstood physical characteristics of a pump is the concept of head. It’s related to pressure, but how, exactly?

This article will demystify the term “head” as it relates to pumps, so you should never have to worry again about what head is, how it relates to pressure or why it’s important.

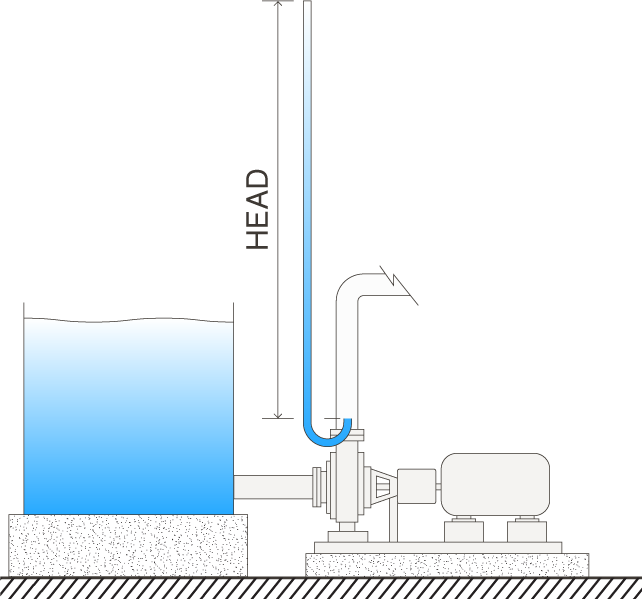

It’s a concept that’s actually incredibly simple to define, but can be confusing when the concept is translated into examples involving real pumps. Imagine a pump where you have a pipe that extends straight up vertically from the discharge (see Figure 1).

Figure 1: Imaginary vertical discharge pipe used to measure head.

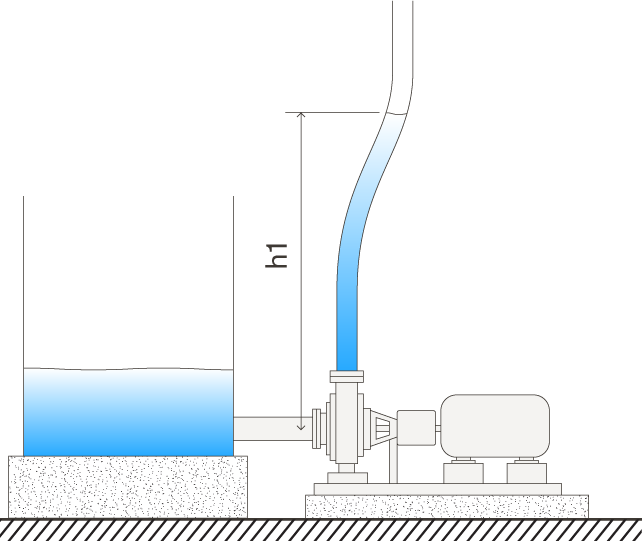

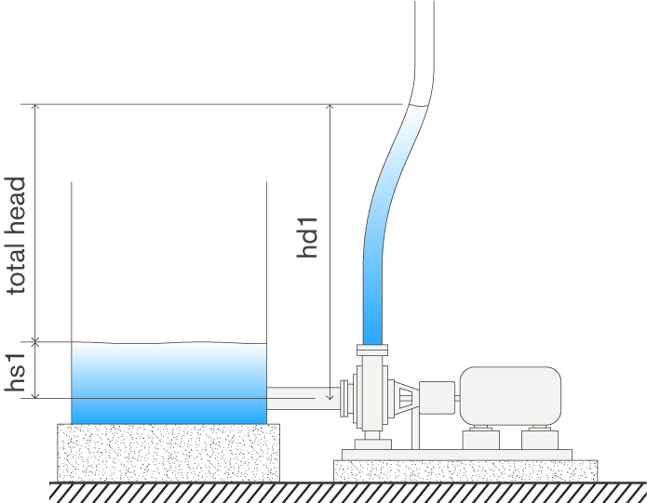

Simply stated: a pump’s head is the maximum height that the pump can achieve pumping against gravity. Intuitively, if a pump can produce more pressure, it can pump water higher and produce a higher head. Also note that the higher the liquid in the tank, the higher the pump will be able to pump the water into the vertical discharge pipe, due to the head exerted by the liquid in the suction tank (see Figure 2).

Figure 2: Head depends on the pump itself and the height of the liquid in the suction tank.

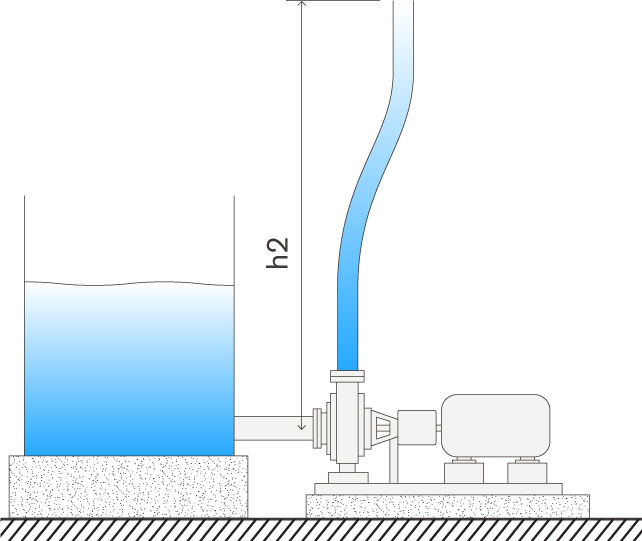

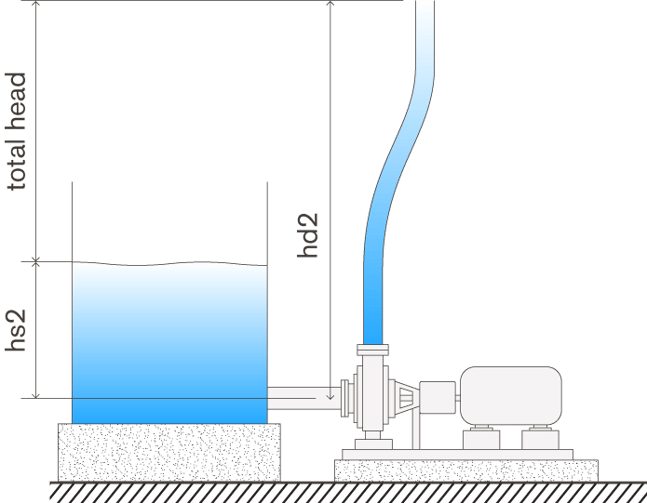

A much more useful measure of head is the difference between the liquid level in the suction tank and the head in the vertical discharge pipe. This number is known as the “total head” that the pump can produce.

Increasing the level of the liquid in the suction tank will give rise to increased head, and decreasing the level will give rise to a lower head. Pump manufacturers and suppliers often won’t tell you how much head a pump can produce, because they can’t predict what the height of the liquid in your suction tank will be. Instead, they will report the pump’s total head, the difference in height between the level of liquid in the suction tank and the height of a column of water that the pump can achieve. Total head is independent of the level of liquid in the suction tank.

Figure 3: Total head is independent of the suction head.

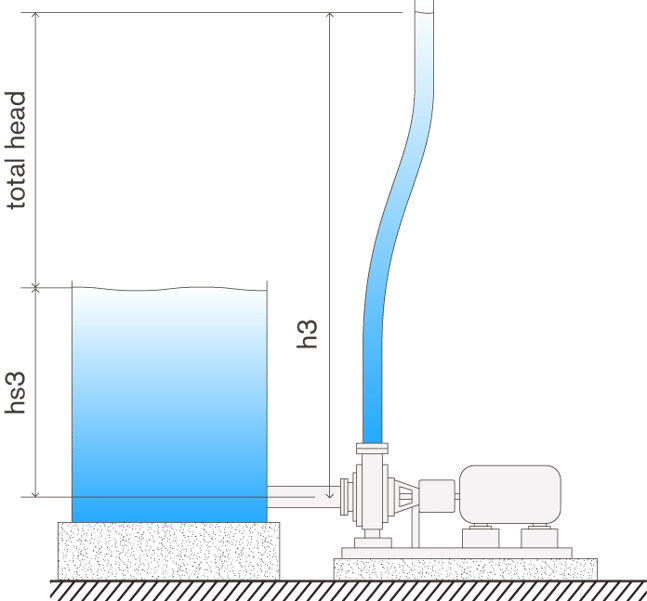

Note that now that we’ve defined total head, we can translate these useful relationships into equations:

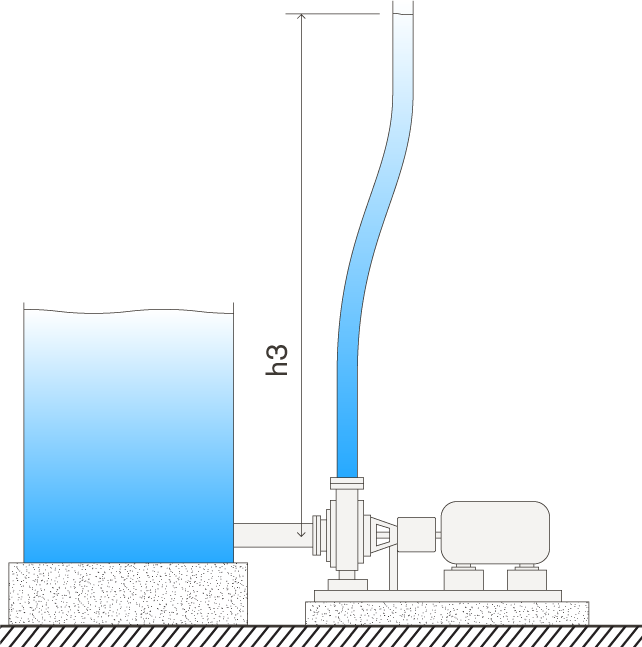

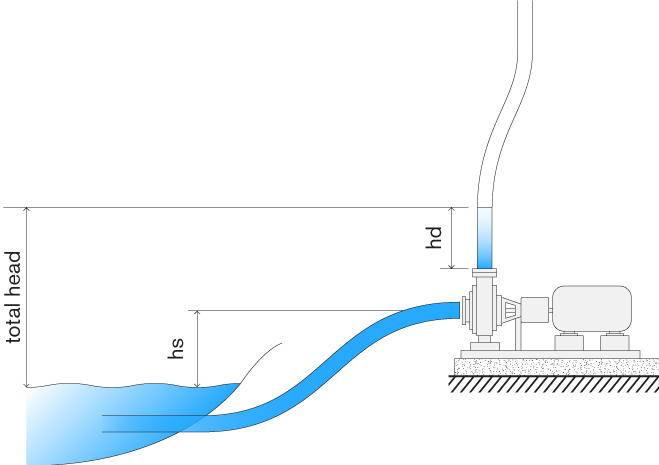

Ht = Hd + Hs

Where Ht is the total head, Hd is the discharge head and Hs is the suction head. Also be aware that this equation holds true whether the suction head is positive (level of liquid in the suction tank is above the pump) or negative (level of the liquid in the suction tank is below the pump). See Figure 4 for an example of the latter situation. In this case, the pump will still produce the same total head, but because the suction head is negative, the discharge head will be reduced by this amount, according to our equation.

Figure 4: Example of how a negative suction head affects the discharge head.

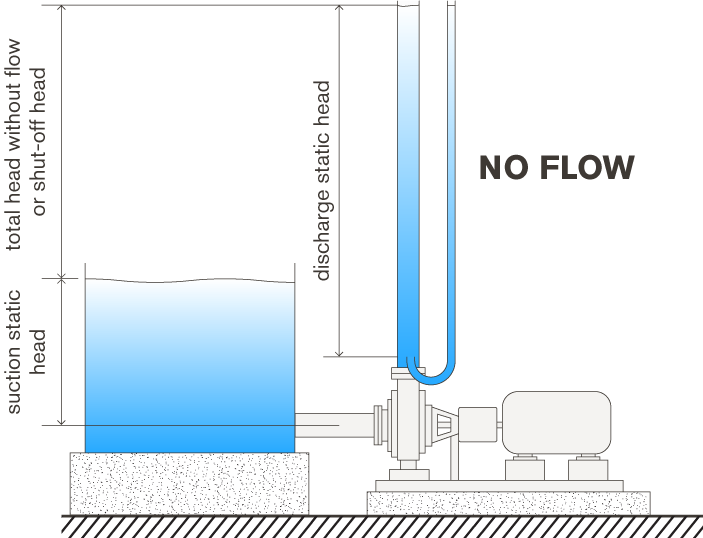

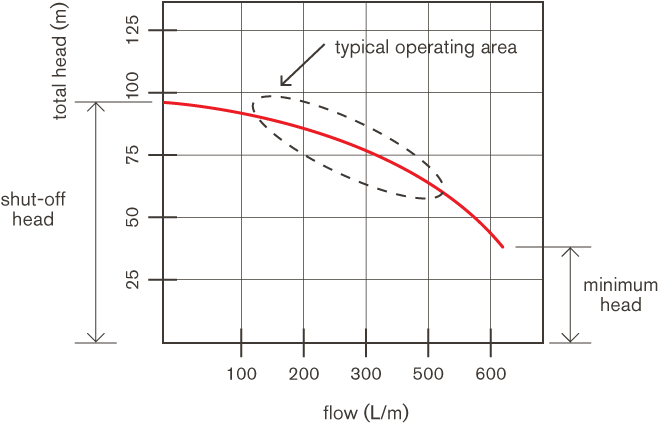

In Figure 5 a pump is transferring liquid from the suction tank into a vertical pipe where the liquid rises until it can’t overcome the force of gravity and it quits rising. In this situation, the flow of the pump is zero. The pump is working, but the force of gravity causes the water’s rise in the vertical discharge pipe to stop and the net flow stops. This is known as the “shut-off head”, it’s the amount of head a pump can produce at zero flow.

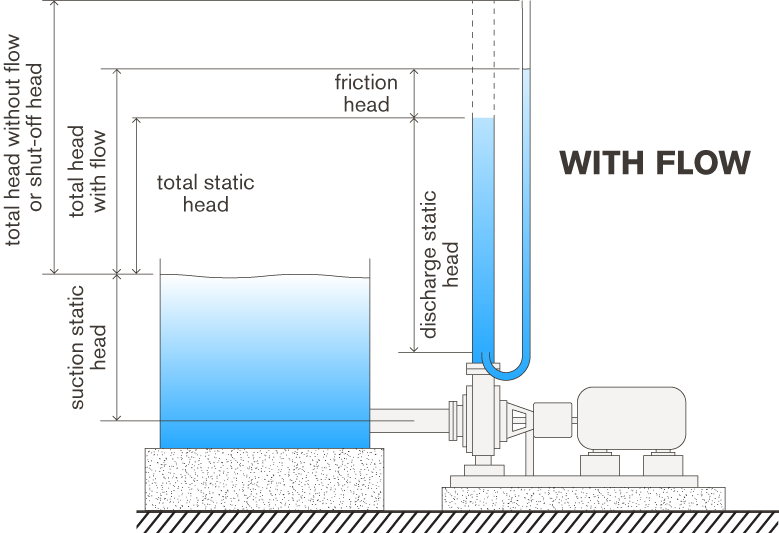

To choose your required pump, you need to know two things: the total head and what flow rate you require. As you might expect, these two quantities are related. The maximum head (shut-off head) is achieved at a flow rate of zero. Increasing flow rate introduces friction into the system as the liquid travels along the pipes from the suction tank to the pump and from the pump into the discharge pipe. This friction reduces the amount of total head that the pump can produce. In fact, as the flow increases, friction increases and the total head continues to decrease. The amount of head that is lost due to friction is called “friction head” or “friction-loss” (see Figure 5 and Figure 6).

Figure 5: Relationship between total head, shut-off head, discharge head and suction head in a pump with no flow.

Figure 6: Relationship between total head, shut-off head, discharge head and suction head in a pump with no flow.

In a system where there is flow, the total head is the difference between the discharge head and the suction head plus the friction head and this sum will be less than the shut-off head. The plot of head versus flow rate is known as the pump’s performance curve (see Figure 7 for an example of a pump performance curve).

Figure 7: Pump performance curve of total head versus flow.

Every centrifugal pump will be supplied with a performance curve plotting head versus flow rate. The required flow rate and total head will intersect at a certain point on the pump’s performance curve and comparing this to the pump’s curve will allow you to determine whether that particular pump will be appropriate (i.e. will it produce enough head at the required flow rate?) for your needs.

Why is head used as a measure of a pump’s ability to pump liquids rather than pressure? Historically, many pumps were used to pump water uphill to a higher level – for example into a storage tank at the top of a hill. If you have to pump water to a height of 60 metres to get it up the hill, then using head – measured in metres – is natural. You automatically know that if a pump doesn’t have 60 metres of head, it’s not appropriate for your application.

Another reason that head is used, is that as long as the liquid that is being pumped has a similar viscosity to water, the head will be identical for different liquids. This may or may not be the case when using pressure to define a pump’s characteristics. Although some pump manufacturers do use pressure to characterise their pumps, the vast majority of pumps are still characterised by the total head they produce.

We hope you found this blog post helpful. Head to our blog page to learn more about how to reduce friction in suction/discharge lines or how to check flow and head pressure.

Global Pumps are a leading Australian industrial pump supplier for mining, government, wine, food, beverage, chemical processing, paint, print, packaging and manufacturing industries. We stock an extensive range of pumps and spares in Australia and deliver anywhere in the world.

Our pump engineers and sales consultants are available to help you to select the right pump or system to suit your specific industry application needs, to achieve efficiencies, increased productivity and reduced downtime. Contact us today to talk to one of our friendly pump experts about what type of industrial pump you need for your specific industry application.

Looking for pump stations?

Visit Global Water

Head Office

12 Selgar Avenue Tonsley

South Australia 5042