At mining operations, quarries or gravel pits, underground dewatering and drainage is a requirement to ensure that mining operations continue unhindered, and provide an environment conducive to providing optimal production due to the high costs associated with operations such as undergound mining. Dewatering from rock faces in stopes in mine shafts, quarries, or gravel pits will often contain abrasives such as sand, clay particles, drill cuttings and other potentially damaging objects.

At mining operations, quarries or gravel pits, underground dewatering and drainage is a requirement to ensure that mining operations continue unhindered, and provide an environment conducive to providing optimal production due to the high costs associated with operations such as undergound mining. Dewatering from rock faces in stopes in mine shafts, quarries, or gravel pits will often contain abrasives such as sand, clay particles, drill cuttings and other potentially damaging objects.

Our team at Global Pumps understand the requirements of these operations, and as part of our ongoing commitment to our customers, we provide relevant information for dewatering and drainage duties.

Why Engage in Dewatering Efforts?

The primary goal is to get water out of the way and to keep it out. On construction sites and mines, water can be an obstacle to excavation efforts. If water levels are not controlled there are negative impacts, not only on the efficiency and economic viability of a project, but also the safety of the workers tasked with getting the job done.

For mines there are even more added benefits, such as: fewer explosives required to clear out dry environments (cost savings), dry ore and waste material weighs less and is easier to move (more cost savings), better working conditions leads to less downtime (even more cost savings), and improved structural integrity of the work area is a safety benefit to all involved.

How is the water removed most efficiently?

Slurry pumps

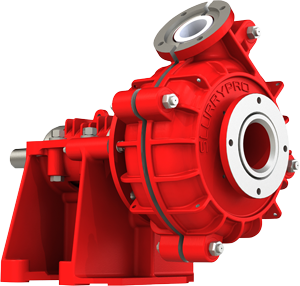

One of the most straightforward and effective is the use of a slurry pump to get rid of excess water. Mine dewatering through the use of slurry pumps uses force (often centrifugal force) to move the mixed up water and rock (slurry) out of an area. These are heavy-duty pieces of equipment that can often be used in difficult environments that would destroy more fragile pumps.

Our Slurrypro series pumps use innovative design features to run cooler for longer, have improved operating efficiency, and reduced downtime.

These pumps are proven performers in the mining industry and made from consistently performing parts that exceed the quality expectations of most end-users.

Helical rotor pumps

Another alternative is the use of helical rotor progressive cavity pumps, skid mounted for this application. Global Pumps have a number of products that fit the requirements. The two most prolific flow rates in this scope are 12 litres per second duties and 20 litres per second duties and the TDH requirements vary, as do our offerings dependent on how many stages we use in the progressing cavity pump.

Global Pumps supply high quality, heavy duty mine dewatering pumps for use in tough environments.

You can rest assured that the products we supply are top-notch, as we have a passion for providing quality gear. We are a well-known name for providing specialised pumps across the country for good reason, and our extensive range of pumps and spares is like no other.

Contact us today to find out more.

If you need some guidance on how to select the right pump then you’re not alone! There’s such a wide range of pumps in Australia, from centrifugal pumps to hose pumps to diaphragm pumps. The options available to you can make it a difficult choice, so we’ve created this special guide to help step you through the process of selecting the ideal pump for your requirements.

Looking for pump stations?

Visit Global Water

Head Office

12 Selgar Avenue Tonsley

South Australia 5042