Our Global Pumps team have been advising best pumping practice in a multitude of industries. Whether it be chemical, manufacturing to mining and quarries, our team understand how critical an effective pumping system is.

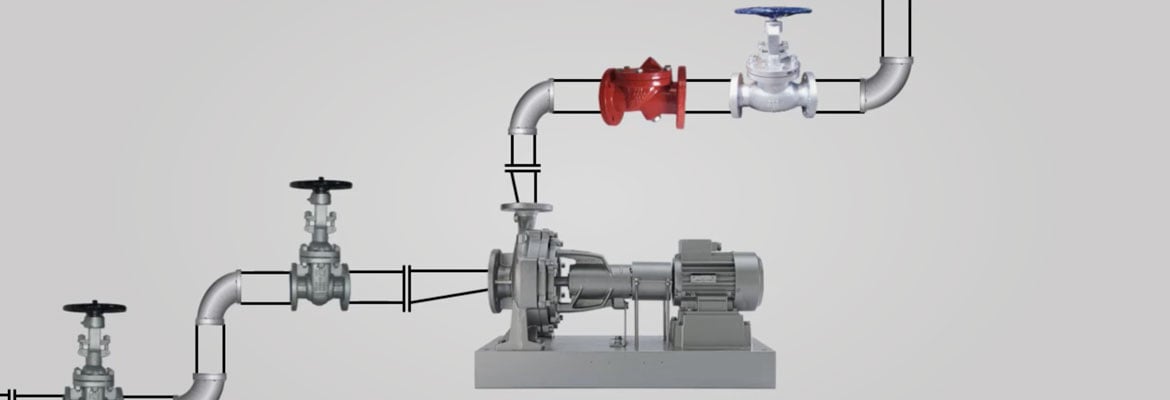

This blog discusses ways in which you can improve the efficiency of your existing pumping system. Particularly, common pumping problems and the potential opportunities that allow for improvements in efficiency.

What is pump efficiency?

Efficiency can have different meanings. Global Pumps consider pump efficiency as how well the pump can convert one form of energy to another, based on the difference between the horsepower going into and out of a pump. We discuss this concept, and how to calculate your pump’s efficiency in this blog.

Common pumping problems and how to fix these

Research has shown that the average pumping efficiency in manufacturing plants can be less than 40%, with 10% of pumps operating below 10% efficiency. It is oversized pumps and the use of throttled valves that generally contribute the most to efficiency loss. In most instances these inefficiencies are not obvious, and opportunities to improve efficiency and save energy are overlooked.

Therefore, Global Pumps suggest determining the limitations of your current system in order to find the best solution to achieving energy efficiency within your operations. The following steps will provide you with everything you need to know:

The following table highlights common pumping problems and methods of improving efficiency.

| Common Pumping Problem | Potential Opportunity to Improve Efficiency |

| Unnecessary demand on pumping system | Reduce the demand placed on the pumping system |

| Oversized pumps |

Select a pump that operates near the BEP |

| Pump wear | Pump maintenance |

| Inefficient impeller | Change impeller |

| Inefficient pump throttling controls | As for oversized pumps Fit adjustable or variable-speed drive |

| Inefficient piping configuration | Change piping inefficiencies |

| Oversized motor | Change motor |

| Inefficient motor | Change to high-efficiency motor |

| Lack of monitoring and/or documentation | Install monitoring Conduct a survey |

If you have determined that your existing pumping system uses a considerable amount of power, consider the following techniques to lower pump energy consumption:

| Energy savings method | Savings |

| Replace throttling valves with speed controls | 10 - 60% |

| Reduce speed for fixed load | 5 - 50% |

| Install parallel system for highly variable loads | 10 - 30% |

| Replace motor with a more efficient model | 1 - 3% |

| Replace pump with a more efficient model | 1 - 2% |

Implementing these simple changes, can save long-term costs associated with energy consumption and maintenance & repairs. Reducing the life-time costs of the pump, can trickle to savings throughout the business, not just the pumping system. For more information on life-cycle costs of pumps, check out this blog.

Want to chat to an expert about your site?

Do you have a question that’s not answered? If so, get in touch with Global Pumps! Our team are available to discuss your specific application, and chat about implementing an efficient and effective pumping solution for your site.