Learn the difference between a positive and non-positive displacement pump thanks to our team of experts at Global Pumps.

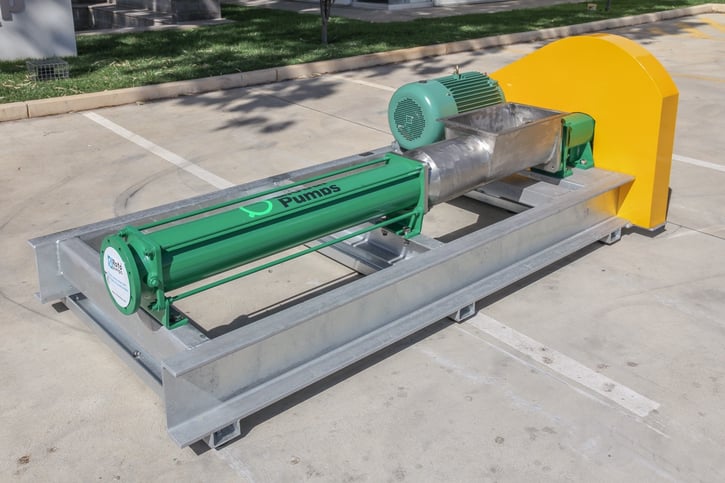

Above: Global Pumps' Helical Rotor Pumps

Above: Global Pumps' Helical Rotor Pumps

What is a positive displacement pump?

A positive displacement pump provides a constant flow at fixed speed, regardless of changes in pressure.

The pump makes the fluid move by trapping a fixed amount and forcing the volume into the discharge pipe. The liquid flows into the pump as the cavity on the suction side opens or expands, whilst the liquid flows into the discharge as the cavity closes or decreases. Through every cycle of operation, the volume is the same.

Examples of positive displacement pumps are:

-

piston pumps

-

rotary lobe or gear pumps

What is a non-positive displacement pump?

A non-positive displacement pump’s output flow rate can change in response to the pressure on the outlet. They use Newton’s first law of motion to move fluid against the system resistance. Although they provide smooth and continuous flows - their flow output is reduced as the system resistance is increased.

Examples of non-positive displacement pumps are:

- Centrifugal pumps

- Multi-stage pumps

- Axial (propeller) pumps

Key differences between positive and non-positive displacement pumps?

|

|

Positive Displacement Pumps |

Non-Positive Displacement Pumps |

|

Pressure |

Work in high pressure applications, up to 800 bar |

Used for low pressure application, maximum pressure of 18 to 20 bar |

|

Efficiency |

Efficiency increases with increasing pressure |

Efficiency peaks at best-efficiency-point. At higher or lower pressures, efficiency decreases |

|

Viscosity |

Efficiency increases with increasing viscosity |

Efficiency decreases with increasing viscosity due to frictional losses inside the pump |

|

Performance |

Flow is constant with changing pressure |

Flow varies with changing pressure |

For more information on positive or non-positive displacement pumps, contact the team at Global Pumps. Our experts have over forty-years’ experience solving tough pumping challenges.