Verder supply peristaltic pumps and AOD pumps to help in the process of manufacturing roof tiles.

During the manufacture of clay roof tiles, several processes that require pumps are utilised. Acid etching, pigment or paint application, coating with environmentally protective materials to increase resistance of the tiles to inclement weather, are all examples of pump requiring steps in roof tile production. One such tile manufacturer was unhappy with the customer service provided by its incumbent pump supplier and turned to Verder to help solve their challenging pumping requirements.

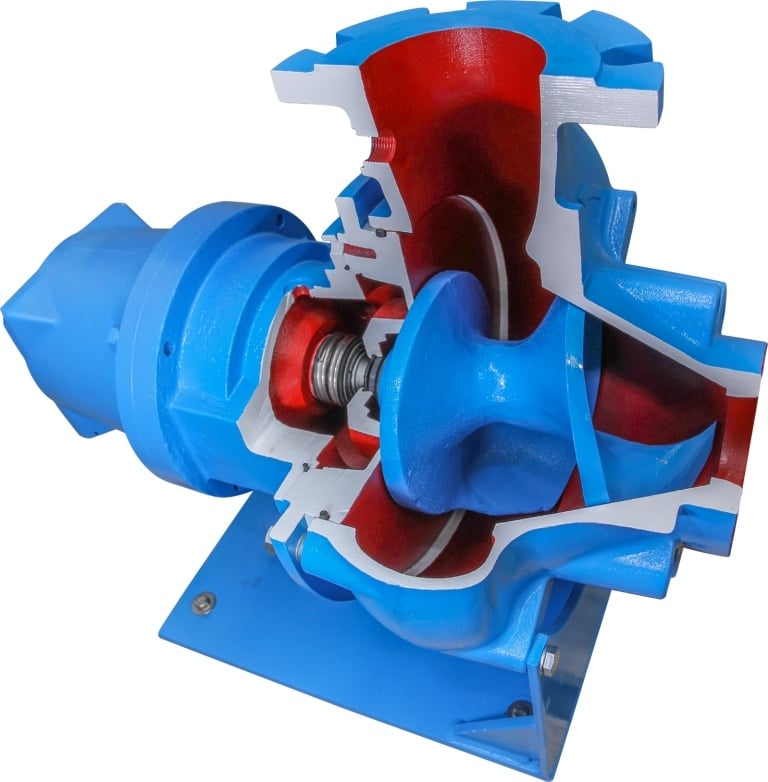

Verder sent a local representative to consult with the company’s engineering team. There were several major challenges that the ideal pump had to overcome in an economically viable manner. First, the coatings that were applied contained abrasive particles so the pump had to be resistant to abrasive fluids. Second, the acid etching solution was recirculated during the etching process using a pump, so that pump, in particular, had to be resistant to the acidity of the process fluid, but also to abrasive particles that were released into the solution during etching. The Verderflex VF25 peristaltic hose pump was identified as an ideal solution to apply the spray coatings for several reasons. Peristaltic pumps are by their nature, resistant to abrasive containing process fluids. A shoe on the pump’s rotor provides the pumping action by compressing the tube as it rotates. As the shoe seals the tube and rotates, it creates suction, drawing liquid in from the pump’s inlet and expelling it from the pump’s outlet. The tube undergoes compression followed by relaxation, and the number of compressions, rather than the abrasive nature of the process fluid, is what causes the tube to wear. Verder’s flexible hose dampens any pulsation induced in the system and this provides an even discharge through the spray system resulting in an extremely even coating on the tiles.

In addition to providing a solution to drive the spray coating system, in the form of Verder’s VF25, Verder was also able to recommend the Verderair VA25, its air operated double diaphragm (AODD) pump to recirculate the acid during the etching process. Although available in a variety of materials, Verder’s consultant suggested the solid PTFE version, metal-free and manufactured with 100% virgin PTFR as this construction provides the acid resistance required for this method. In addition, its diaphragms are uniquely designed for long-lasting, air-conserving operation. Coupled with these features, the VA25 is extremely abrasive resistant satisfying all the requirements for this procedure.

In fact, the VA25 was such a success, that the manufacturer standardised their tile-painting system with these pumps as well. The reasons cited for this are the VA25’s exceptional reliability, low cost of maintenance and its ability to handle the high viscosity paint, not to mention Verder’s incomparable attention to customer satisfaction. Other advantages to the VA25 include its resistance to most corrosive chemicals and abrasives. As mentioned previously, the advanced operation of the reciprocating diaphragms results in less wasted air per cycle, saving massive amounts of compressed air, again contributing to the VA25’s low total cost of ownership, releasing less gas to the environment and pumping more fluid per cycle.

Global Pumps is a supplier of the Verderflex peristaltic hose pumps and the Verderair diaphragm pumps.