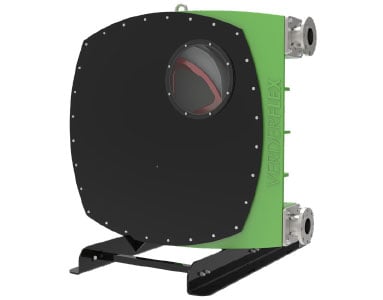

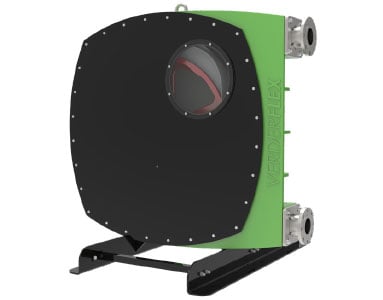

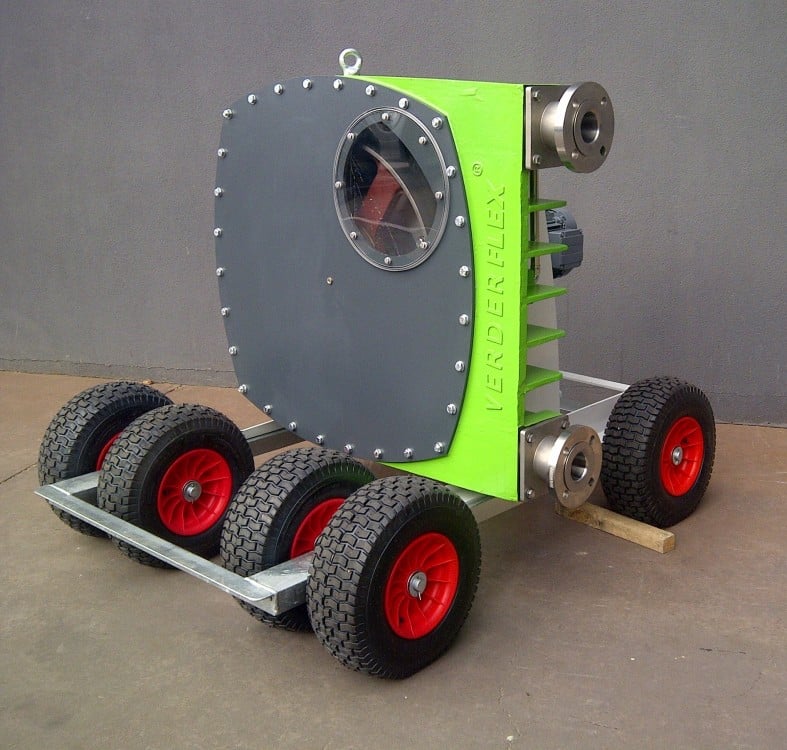

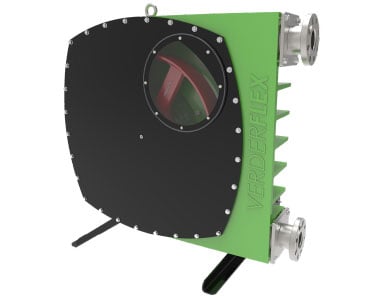

Verderflex Ds4F

The Ds4F Peristaltic tube pump offers exceptional flexibility, allowing you to easily handle a variety of chemicals and materials by using different tube sizes and materials within the same pump. Ideal for precise and consistent liquid dosing, it’s perfect for industries like water treatment, mining, and pharmaceuticals. With flow rates ranging from 1 to 4,000 mL/min and pressures up to 4 bar, this pump is built to deliver high performance. Featuring IP66/Type 4X protection, IoT connectivity, and reversible operation, it excels in harsh environments. Its low-maintenance design minimises downtime and reduces long-term operating costs.