Learn how Visy saved time and money by using a Verderflex peristaltic pump.

Challenge

Visy, a 4-colour printing business, uses pumps to deliver inks to its printers. The AODD pumps they were using considerable amounts of compressed air and required constant maintenance due to the wearable parts (seals and valves). This was resulting in unacceptably long downtimes and high cost of repair and parts. The customer wanted pumps that would offer increased durability and low maintenance, decreasing the cost of ownership by lowering repair/service costs. In addition and more importantly, the pumps needed to deliver the shear sensitive inks to the printers without foaming or separation.

Solution

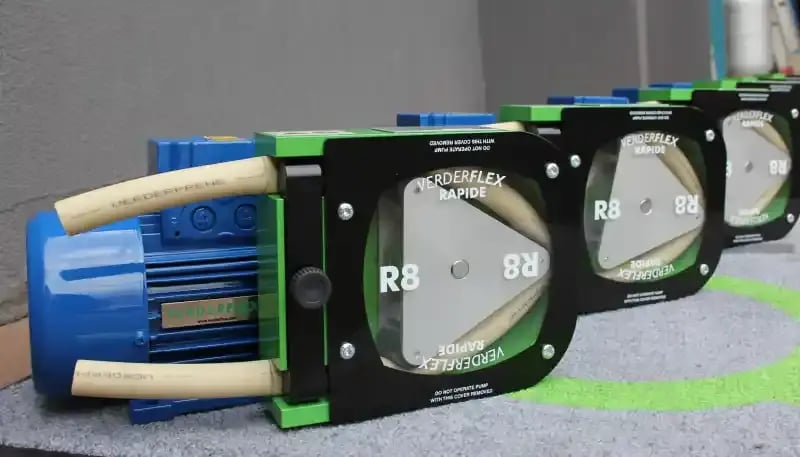

After assessing the situation, Global Pumps was able to recommend the Verderflex R8 Peristaltic Hose pumps to replace their Wilden M1 AODD pumps. With a flow rate between 170 l/hr and 470 l/hr at 2Bar, the low maintenance Verderflex R8 was perfect for their application. The pumps enable the customer to saving both cost and time by having high dependability and only one wearing part – the hose. With a simple clamping mechanism enabling hose change, the pumps are easy to maintain onsite, without requiring specialist repairs. There are no seals or valves to replace, nor impellers that can become clogged.

Result

The result? A very happy customer who claims the Verderflex R8 is a “great pump and very reliable”. In addition to the benefits described above, our customer was delighted that the pumps also save money on ink during setup/cleaning between jobs by being reversible. They simply pump any unused ink back into the supply after the print job is finished.

Get in touch with our experts at Global Pumps regarding our range of peristaltic hose pumps for your application.