Why Air Operated Double Diaphragm pumps?

Air operated diaphragm pumps or pneumatic diaphragm pumps are reciprocating pumps where the working elements are flexible diaphragms. The control is by means of compressed air being applied to the Air Valve incorporated into the pump. The air valves’ unique design guarantees a perfect, non-stalling operation, even at low pressure and does not need any lubrication.

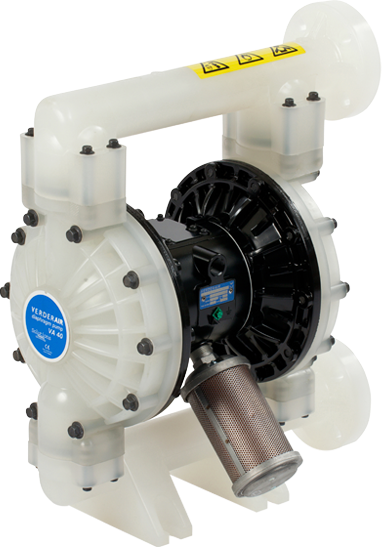

Backed by extensive research and development, the Verderair® pump range are the AOD pumps we trust and supply to our customers. Verderair® offer an extensive choice of materials, with the diaphragm pump series available in both metallic and non-metallic options to suit the application.

They have the capability to transfer even the stickiest of substances, including slurry and solids in addition to standard water like liquids.

We have many varieties of Verderair® AOD pumps AOD pumps that guarantee the safe, efficient and controlled transfer of all types of liquids and chemicals.

Click here to download a free copy of our “AODD Cheat Sheet” to see which product is right for you, or call on of our specialists on 1300 145 622.

Features:

Leak free air operated diaphragm pump

Air operated diaphragm pumps are leak free because they don’t have plungers or piston rods which pass through the pressure boundary. A leakage can only occur if the diaphragm, also referred to as the membrane, breaks. In preventive maintenance, or to avoid breakdowns, it is necessary to replace the diaphragms.

Variable flow

The double diaphragm pump will provide variable flow and discharge pressures of up to 870 kPa by simply adjusting the air supply. The compressed air can be used to balance liquid pressure and give high discharge capability. A single air pump can provide a broad spectrum of pumping capabilities from a few litres up to 1,060 l/min.

Dry running capabilities

Air operated double diaphragm pumps have outstanding dry run capabilities. These pumps are designed to run dry indefinitely without damage. The AOD pumps are also self-priming from a dry start. The Air Operated Double Diaphragm pump can also run completely submerged or installed with flooded suction. For ease of maintenance, they don’t require gland packing and there are no close-fitting, sliding or rotating parts to maintain.

Capabilities

As flow and discharge of the air operated diaphragm pump or pneumatic diaphragm pump is infinitely variable (as mentioned above) one pump can be used for an extremely wide range of capabilities. This eliminates the need for costly motor drives and critical calculations.

Why Verderair?

Besides the general advantages of any air operated double diaphragm pumps on the market, Verderair offers many other advantages for users. Having a wide range of proven products for different applications Verderair offers experience. Verder (diaphragm pump-set manufacturers) has over 50 years of experience with applications for the air operated diaphragm pump. This experience comes from both the industrial and sanitary segments.

Stock

Generally, people expect Air Operated Double Diaphragm pumps to be available on a short term. Therefore Verderair works with an efficient stock-management (for both pumps and parts) and flexible production. With this, Verderair offers a real advantage if you need a pump within a short time frame.

Global Pumps supply businesses across all industry sectors with the most advanced diaphragm pumps Australia.

The air operated diaphragm pumps Australia we stock are from the Verderair® range, which uses compressed air that is effectively shifted from one chamber to another by a linking shaft. The simultaneous back and forth motion forces product out of one chamber, while the opposite chamber is being consistently re-filled to create a continuous cycle.

Within the air-operated range, we have products which differ in port size, flow, and pressure. Some of the core features include:

- Self-priming capabilities

- Robust construction

- Anti-freeze/anti-stall and lube free

- Externally serviceable air distribution systems

- Non-metallic construction to reduce corrosion, weight and cost

- Various elastomer options

We stock a range of other pumps for various industries such as peristaltic hose pumps, chemical pumps, drum pumps and more.

For more pumping solutions delivered Australia-wide, contact Global Pumps now.