FAQs

What pumps are available as fire pumps?

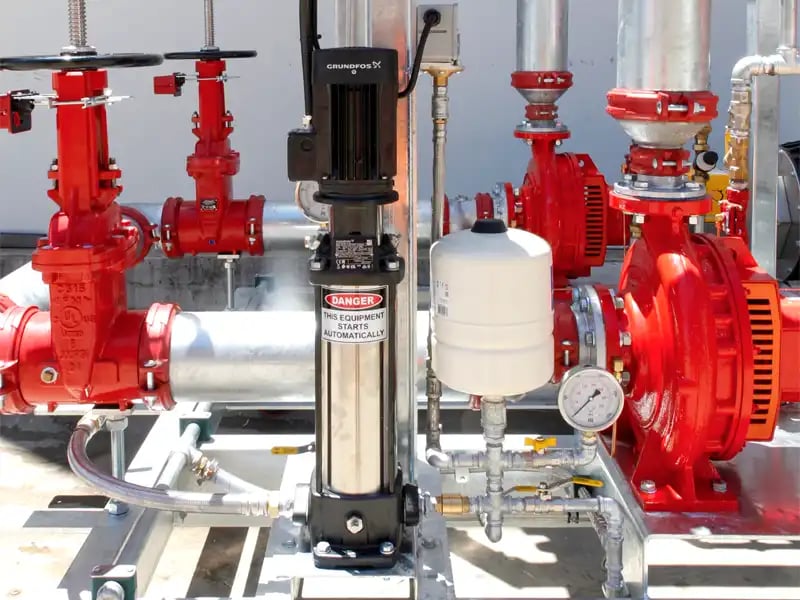

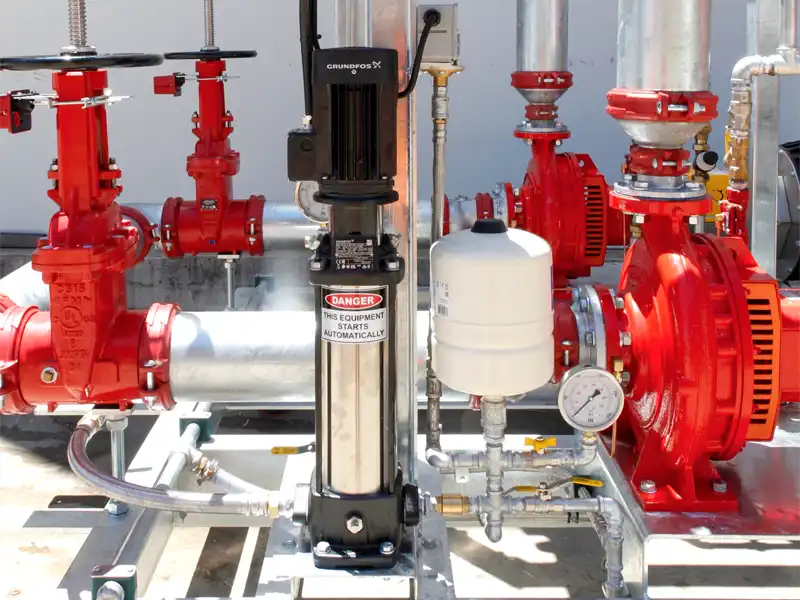

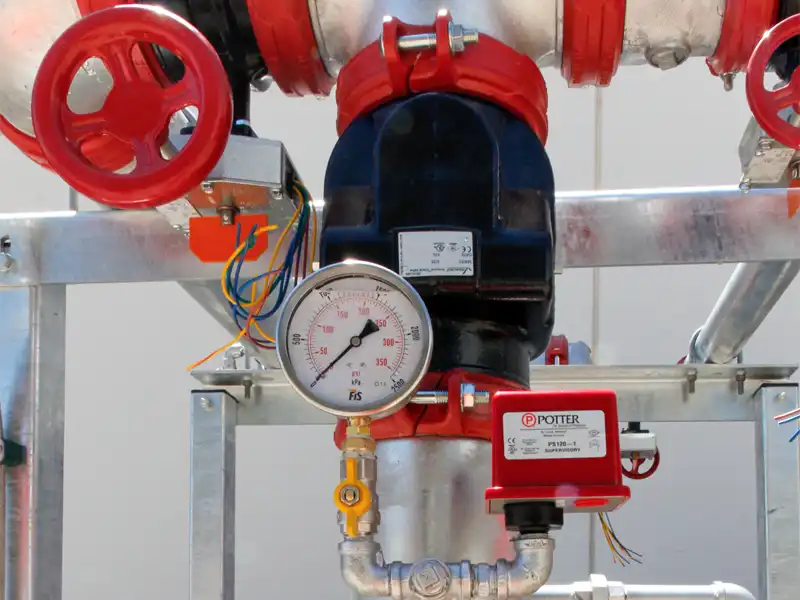

The scale and size of the pumps will vary depending on your application, however in most instances ISO end suction centrifugal pumps are utilised in fire pump set-ups.

End Suction Pumps are high efficiency, high performance and high quality end-suction pumps. These pumps are available in cast iron and stainless for use in these applications.

Please see our essential guide to fire pumps blog for more information about diesel vs electric fire pumps.

Are these fire pumps customisable?

Yes, our fire pumps can be customised to suit your application's demands and requirements.

What compliance do these fire pumps offer?

All pumps are manufactured to Australian Standard 2941-2013 and the Intent of American Fire pump standard, NFPA20.

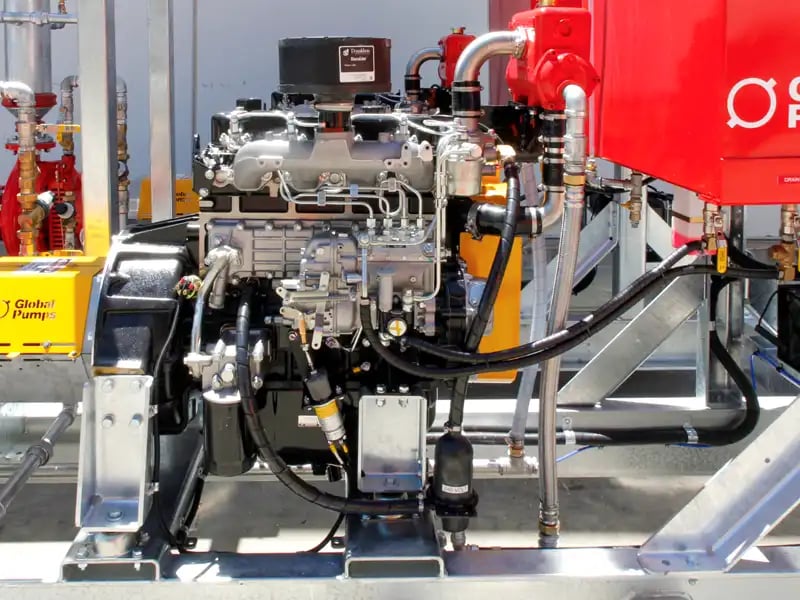

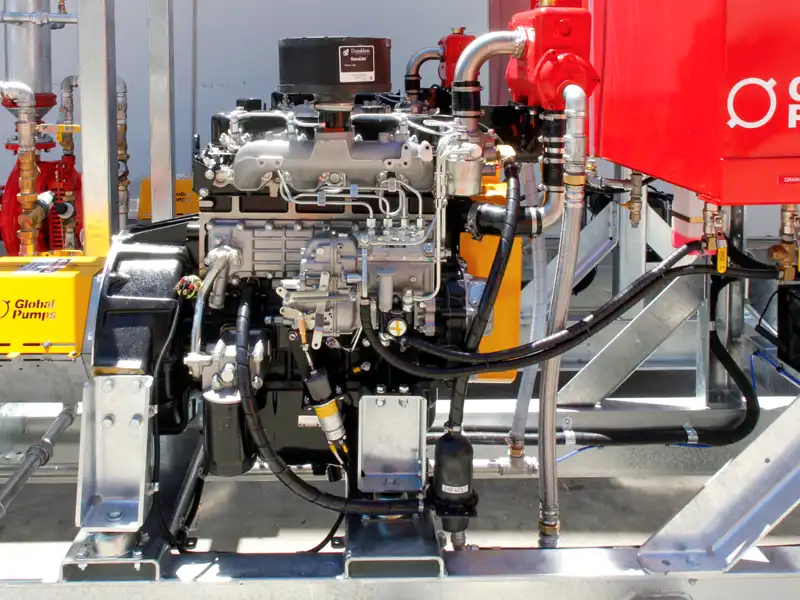

DIESEL FIRE PUMPS

Does the fire pump include a fuel tank?

A: Absolutely! The pump comes equipped with a factory-mounted fuel tank sized for a 6-hour runtime, ensuring you have the fuel needed for extended operation.

How can I reduce noise from the fire pump?

A: We understand noise reduction is important. While sound attenuation isn't included as standard, we offer various silencer options to fit your needs. Additionally, if you choose a pump enclosure, we can incorporate acoustic panelling for further noise reduction.

Are spare parts included with the fire pump?

For your peace of mind, the pump includes a lockable, galvanised toolbox containing essential engine spare parts. This ensures you have readily available replacements for critical components.

Can I get a custom enclosure for the fire pump?

Yes! We offer the flexibility of factory-installing your pump within a custom-built enclosure that perfectly suits your application. Alternatively, we can modify a container to house the pump.

Does Global Pumps provide installation services?

While we don't offer direct installation services, we can provide you with detailed installation instructions and support to ensure a smooth setup process.

ELECTRIC FIRE PUMPS

Can I get a custom enclosure for the fire pump?

Absolutely! We offer the flexibility of factory-installing your pump within a custom-built enclosure that perfectly suits your application. Alternatively, we can modify a container to house the pump.

Does Global Pumps provide installation services?

While we don't offer direct installation services, we can provide you with detailed installation instructions and support to ensure a smooth setup process.

Are motor starters included with the fire pump?

Yes, the control panel includes a soft-starter for the motor, ensuring a smooth and reliable startup process for your pump.

How long does it take for a fire pump set to be built?

Below is a guideline of how long it takes to build according to your specifications. Excluding design review and sign-off, a set will typically take:

| Product range |

Timeframe |

| Diesel Fire Pump set |

6-8 weeks |

| Electric Fire Pump set |

6 weeks |

| Diesel/Electric Fire Pump Set |

8 weeks |