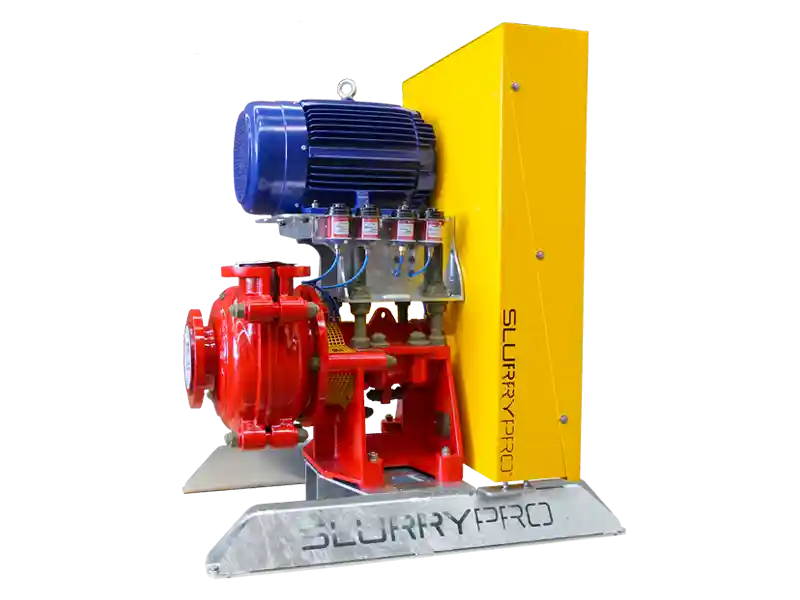

Benefits of choosing SlurryPro horizontal slurry pumps

SlurryPro horizontal slurry pumps are designed for those who seek maximum durability, ease of maintenance, and reduced lifetime costs. Key benefits include:

- Superior wear resistance: Whether you opt for rubber or metal linings, SlurryPro pumps are designed to withstand abrasive slurries.

- Low maintenance costs: The cartridge-type bearing assembly and split casing design minimise downtime and allow for quick and easy repairs.

- Flexible material options: Choose from high chrome, rubber, or polyurethane wearing parts to meet the demands of your specific slurry application.

- Customisable sealing systems: With options for different seal types, including mechanical shaft seals, SlurryPro pumps ensure efficient operation without gland water, ideal for water-sensitive environments.

Whether you require slurry pumps for mining, chemical processing, or other industrial applications, SlurryPro’s horizontal slurry pumps offer comprehensive solutions. Their robust design, coupled with flexible material and part options, makes them ideal for handling even the most abrasive and corrosive slurries. Explore our range of SlurryPro horizontal slurry pumps today to find the perfect fit for your slurry pumping needs.

Comprehensive solutions for industrial slurry pumping

Whether you require slurry pumps for mining, chemical processing, or other industrial applications, SlurryPro’s horizontal slurry pumps offer comprehensive solutions. Their robust design, coupled with flexible material and part options, makes them ideal for handling even the most abrasive and corrosive slurries.

Explore our range of SlurryPro horizontal slurry pumps today to find the perfect fit for your slurry pumping needs.